Ethiopian CirclE Farm V 1.0

In collaboration with Xsyn corporation (USA) and BEDEBO e.a.d.s.c. (ETHIopia) , we are building a low cost circle farm designed for the developing world.

Potential pilot projects could establish a technology demonstration hubs in Ethiopia (4x locations) in a school setting. The schools could be linked with International agricultural schools , farmers, and communities. The hubs in Ethiopia will be linked among themselves and with the school and Slow Tools for knowledge sharing of farming best practice and local innovation. The hubs will serve as a location where local farmers come to learn about and use the Circle Farm tools and small-scale irrigation while allowing the credit score team (supported by SuperFluids Lab) to conduct interviews relevant for them to profile farmers. The credit score team will also collect information on mobile phone and SMS usage habits from the farmers and the telecom service provider and/or local agent. Based on this initial profiling through interview and mobile phone usage, model farmers will be selected to participate in the following programs:

Agricultural Input Program - Receive improved seed on credit

Mechanization Service Program - Receive a multi-crop threshing equipment to provide threshing service

for small holder farmers at a fee.

Perishable Service Program – Agricultural Input Program participant will also receive standardized crates

for collecting their perishable produce for storage at a fee

Project Proposal

The proposed pilot project is an inclusive value-chain based bundled services to SSP enabled by credit scoring to evaluate credit worthiness of SSP establishing trust.

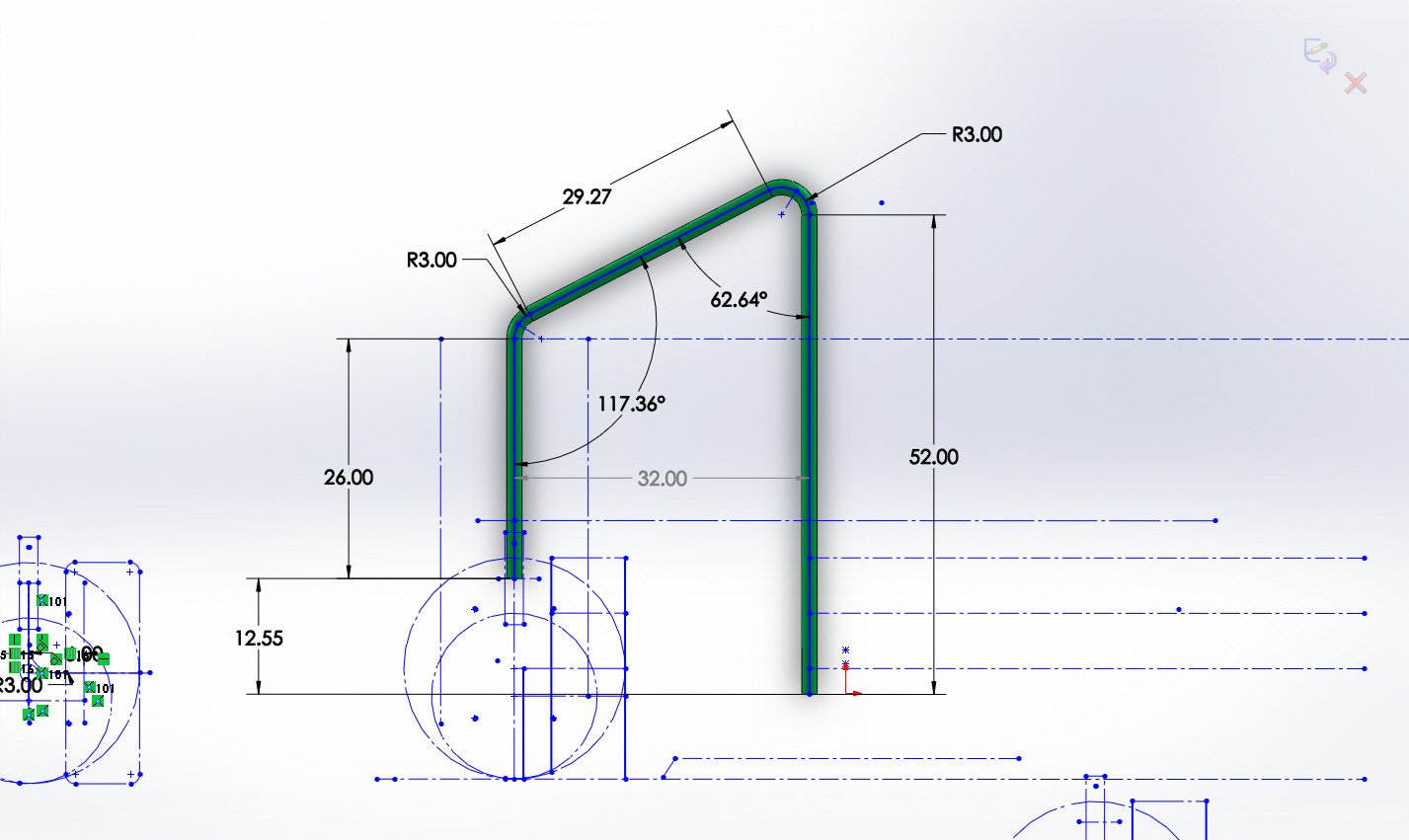

The proposed mechanization is based on a rotating beam with a sliding carriage to which existing and emerging SSP tools are attached. The carriage and tool can be easily positioned and locked anywhere along the beam. Thus, the rotation of the beam creates a precise circular path for basic tools used for seed bed preparation, seeding, cultivating, precision or broad watering, and in some cases, harvesting of certain crops – with the added benefit of reducing the effort and skill required to accurately guide tools while walking or driving between the plants, an effort that increases soil compaction, reduces soil fertility, and takes away productive area.

Each of the 4 proposed 18m diameter circles has a net area of 220 square meters, and therefore a typical total planting row length of 400 to 700 meters depending on planting circle radius spacings of 30 to 50 cm. In addition, the area in between the 4 circles can be used for perennial crops, berries, herbs, and fruit/nut trees. It is currently practical to increase the circle diameter to 30 meters, which more than doubles the planting area. Thus, at their highest plant density, the proposed 4 circles have a total row length of 2.8 Km.

Depending on the tool resistance and flatness of the ground, the beam can be rotated with a little as 200 Newtons. Thus, the beam can be rotated by human, animal, or small electric motor power typically in the range of 350 to 750 w using solar recharged batteries, hence suitable for woman. The battery powered version can be started and stopped with a simple wireless control or cell phone.

A third generation software controlled instrumented version of the circle farm is under development by Slow Tools Inc in the US. These programmable features could possibly be added economically to the current project circles, as standalone controls or connected through the SSP broadband hub. Because the precision of the tool position is mechanical and referenced to a central fixed center point, the upgrade does not require GPS or other reference sensing outside the circle itself. Thus we can now predict at least 2 cm or better positional accuracy and repeatability within a 30 m diameter circle farm which may be critical in planting arrangement resilient to highly non-linear climate events.